The purpose of extrusion processing by twin screw extruder is to transform the viscosity polymer medium through physical and chemical changes by precise control of processing conditions, and produce high quality structured products. The test center provides manufacturers in all industries with expertise and specialized equipment to try out new compounds and improve manufacturing processes. With the participation of our experts, the design, prototyping, testing, and pre-industrial preparation of new compounds can be independently tested on a small scale in our plants and put into mass production scaled up to a reliable scale.

Processing Equipment

The equipment and components can be used in a variety of applications such as food and animal food, environmental-protection plastic, chemical, environmental-protection building materials industries. Our equipment ensures that all aspects of the entire process system comply with the latest process design standards.

Equipment Characteristics

Together with domestic and foreign counterparts, we will contribute to the development of the world food industry to create a better world

Excellent versatility enables continuous processing in one machine for mixing (micro and macro mixing), kneading, melting, degassing and molding materials.

Continuous treatment of reaction, mixing and kneading.

Specialized screw profile to ensure high quality mixing and correct dispersion of the pigments.

Control the fusion, cooling, molding and degassing of the product.

Premix pigments and polymers, the feeding can be conducted through upstream metering system or injected later in the process.

A variety of properly treated raw materials can be used to make compounds with different viscosity and densities and other characteristics.

High productivity and cleanliness.

Short standing time to protect the temperature sensitive materials.

A high level of mechanical torque can increase the productivity.

Equipment Specification

Together with domestic and foreign counterparts, we will contribute to the development of the world food industry to create a better world.

Optional Configuration

The concept of modular design is conducive to the realization of product upgrading and new product development. The equipment can be extended according to the market demand, which can not only realize the current product upgrading but also meet the requirements of new product development. You don't need to replace the whole machine, just need to replace some functional parts you can greatly improve the flexibility of the system which is more economical.

1. Control system: general- control equipment cabinet and intelligent- control equipment cabinet

2. Power module: conventional power module, overloading power module, high-torque power module

3. Feeding system: single screw feeding, twin screw feeding, intelligent metering feeding

4. Cylinder module: integral cylinder module, wear-resistant and composite cylinder

5. Temperature control system: electric temperature control, steam temperature control, module temperature control

6. Extruding module: customize according to process requirements

7. Rotary cutting feeding system: rotary cutting of forward direction, rotary cutting of side direction

8. Main engine base: carbon steel plastic spray frame, stainless steel frame

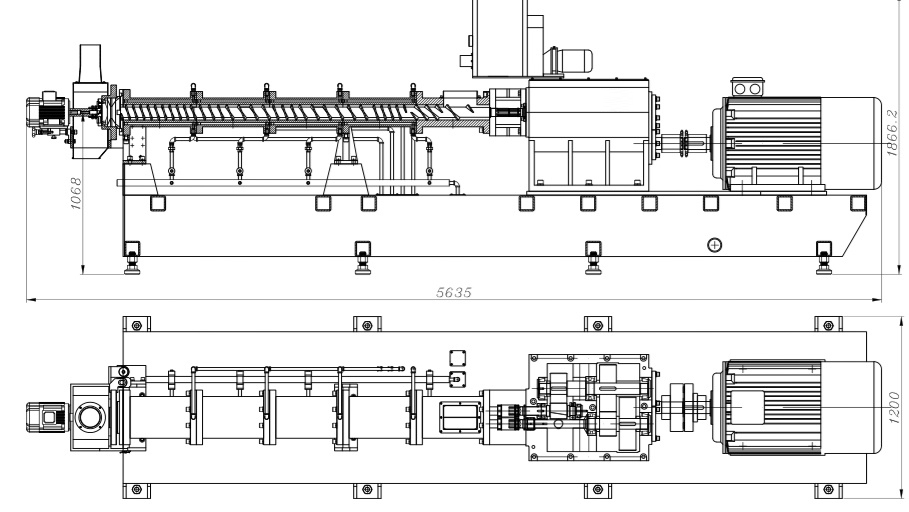

Boundary Dimension

Application Example

Together with domestic and foreign counterparts, we will contribute to the development of the world food industry to create a better world